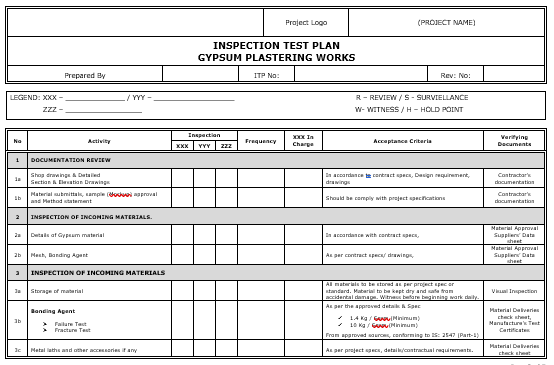

WHAT IS AN INSPECTION AND TEST PLAN

Inspection and Test Plan and checklists are an integral part of quality management system not only in construction but in almost every industry where Quality Management System are in place. It is considered to be master documents through which different parameters and actions of a process or an activity would be monitored and recorded which plays a vital part during the verification later or in simple terms during auditing.

Purpose of an Inspection and Test Plan

- To define quality objectives for each activity or process.

- To specify who will perform inspections and at what stages.

- To establish acceptance criteria in line with specifications, standards, and codes.

- To identify types and frequencies of inspections and tests.

- To determine the responsibilities and approval authorities for all involved parties (Contractor, Consultant, Client, or Third Party).

- To ensure traceability through inspection records, test certificates, and checklists.

In construction industry, where there are a lot of activities, for a variety of trades such as structural., Finishes, Façade, Electrical, Mechanical, Plumbing etc. are to be completed spanning across excavation for foundation to handing over stage, thereby Preparation and implementation of different inspection test plans forms the most crucial part of project management system

Common Structure of an ITP

Typical stages in an ITP include:

- Documentation Review – Verification of approved drawings, submittals, and specifications.

- Material Sample Submittal – Approval of materials before use.

- Incoming Material Inspection – Verification of received materials.

- Pre-Work Inspection – Ensuring site readiness and compliance before work begins.

- In-Progress Inspection – Continuous monitoring of ongoing activities.

- Post-Work Inspection – Final checks after work completion.

ITP explains what to do with each stage of this process, as follows. (Types of Inspection Status Codes)

Activity:

Details about the control activity to be carried out e.g. documentation review (Eg: Whether drawings are approved), checking of materials (Eg: Checking of materials delivered is approved one or not), pre-work inspection (Eg: Inspection of preparation of plastering), etc

Inspection:

Defines the mode of inspection for each inspecting party involved (Contractor, Owner, Consultant, Third Party): It constitutes the following points as applicable depends on the nature of activity to be inspected

Review (‘R”):

Review of documents and formal approval of document is without which work cannot proceed (inspection reports, test certificates, drawings, etc.

Hold (‘H’):

A ‘Hold’ point defines a point beyond which work may not proceed without approval from the inspecting party(ies).

Witness (‘W’):

A ‘Witness’ point provides the inspecting party(ies) with the opportunity to witness the inspection or test or aspect of the work, at their discretion. Information to be passed to them but not necessary to wait for inspection beyond the assigned time for the same.

Surveillance (‘S”):

Intermittent monitoring of any stage of the work in progress as the work progress. Observations are to be rectified once noticed during surveillance.

Frequency: Frequency of inspection activity e.g. each joint, 10%, first time, daily, random etc.

Approving Authority: Details about the party(ies) who has been authorized to conduct the respective inspection

Acceptance Criteria: Criteria with which the documents, the tests, or the works must comply with to be accepted (with reference to design, specification, codes, contracts, or workmanship standards), If not mentioned in the contract (e.g. workmanship), these criteria must be discussed and agreed upon with the contractor before the start of the works.

Verification Record: Documents recording the quality check and acceptance for each document review or inspection. The records may be of different types: approved document, checklist, test certificate, material approval, survey data, etc.

GENERAL NOTES – Preparation Of Inspection and Test Plans

Generally, it is the responsibility of the QA/QC department to prepare the required Inspection and Test Plans for all the activities related to project parameters. The following approach can be used as a guideline for the preparation

REVIEW OF CONTRACT DOCUMENTS

The person in charge of preparation reviews the contract documents, including technical specifications, and prepares a list of any discrepancies, ambiguities, missing information, and standards of materials and/or workmanship that are deemed inappropriate. Issues shall be clarified and resolved with the Consultant, Client, or Designers.

INSPECTION AND TEST – LIST AND SCOPE

The person in charge examines the scope of work and divides it into separate trades requiring each a different ITP. The list of ITPs shall be maintained as a Master list.

Preparation of an ITP

The QA/QC Department is primarily responsible for preparing and maintaining the ITPs for all project activities. The preparation steps include:

- Review of Contract Documents – Identify applicable codes, standards, and specifications.

- Inspection & Test Scope Definition – Break down works into trades (civil, MEP, finishing, façade, etc.).

- Drafting the ITP – Develop a structured plan with defined inspection stages, responsibilities, and records.

- Subdivision of Works – Divide the project into manageable sections for inspection (e.g., floor-wise, area-wise).

- Preparation of Registers & Checklists – Create templates for material approvals, inspection records, and testing documentation.

- Numbering System – Assign unique codes for traceability (e.g., ABC-XYZ-ITP-RCC).

- Submission for Review – Submit the ITP to the Consultant/Owner for approval before commencement of works.

Sample Numbering Format

| Type | Example | Description |

|---|---|---|

| ITP | XXX-YYY-ITP-ZZZ | Company Code – Project ID – ITP Type |

| Register | XX-YYY-REG-ZZZ | For recording material approvals |

| Inspection | XXX-YYY-ISP-LLL-NNN | For individual inspection records |

| Test | XXX-YYY-TST-ZZZ-NNN | For laboratory or field test records |

Importance in Construction

Since construction projects involve multiple trades—civil, structural, finishing, MEP, façade, etc.—each requiring strict quality control, well-prepared ITPs form the backbone of the project’s QA/QC system. They ensure uniformity, accountability, and traceability from the foundation stage to the handover phase.

In summary:

An Inspection and Test Plan is not just a document but a quality assurance roadmap—ensuring every construction activity complies with standards, specifications, and client expectations.