What Is Quality?

Quality is a multidimensional aspect. As perception changes, so does the way quality is seen by different people. There is no universally accepted definition of quality as a reference. Sometimes it is objective, sometimes subjective. What seems best today may face a better version tomorrow.

So, let’s talk about the quality of civil construction — since CivilQualityControl.com is an exclusive place for civil engineers and others involved in construction.

Let’s assume a scenario from real-life incidents — maybe not for all, but surely relatable for a few people out there. It may make it simple to understand the importance of quality during construction works. Everyone dreams of having their own home, even at the cost of lifelong earnings and savings. Many lucky ones realize that dream and own one.

A Real-Life Scenario of Bad Quality

Imagine one fine day, while enjoying the monsoon, water droplets are falling on your head or dining table. Or on another day, when you want to leave for urgent work, you suddenly experience a choking of water lines in your newly owned home.

Both cases are frustrating. And what could be the reason? In simple words, “the quality of the building is bad.” Technically speaking, it means the construction failed to meet the required standards, or a proper quality system to supervise and monitor the works was missing during execution.

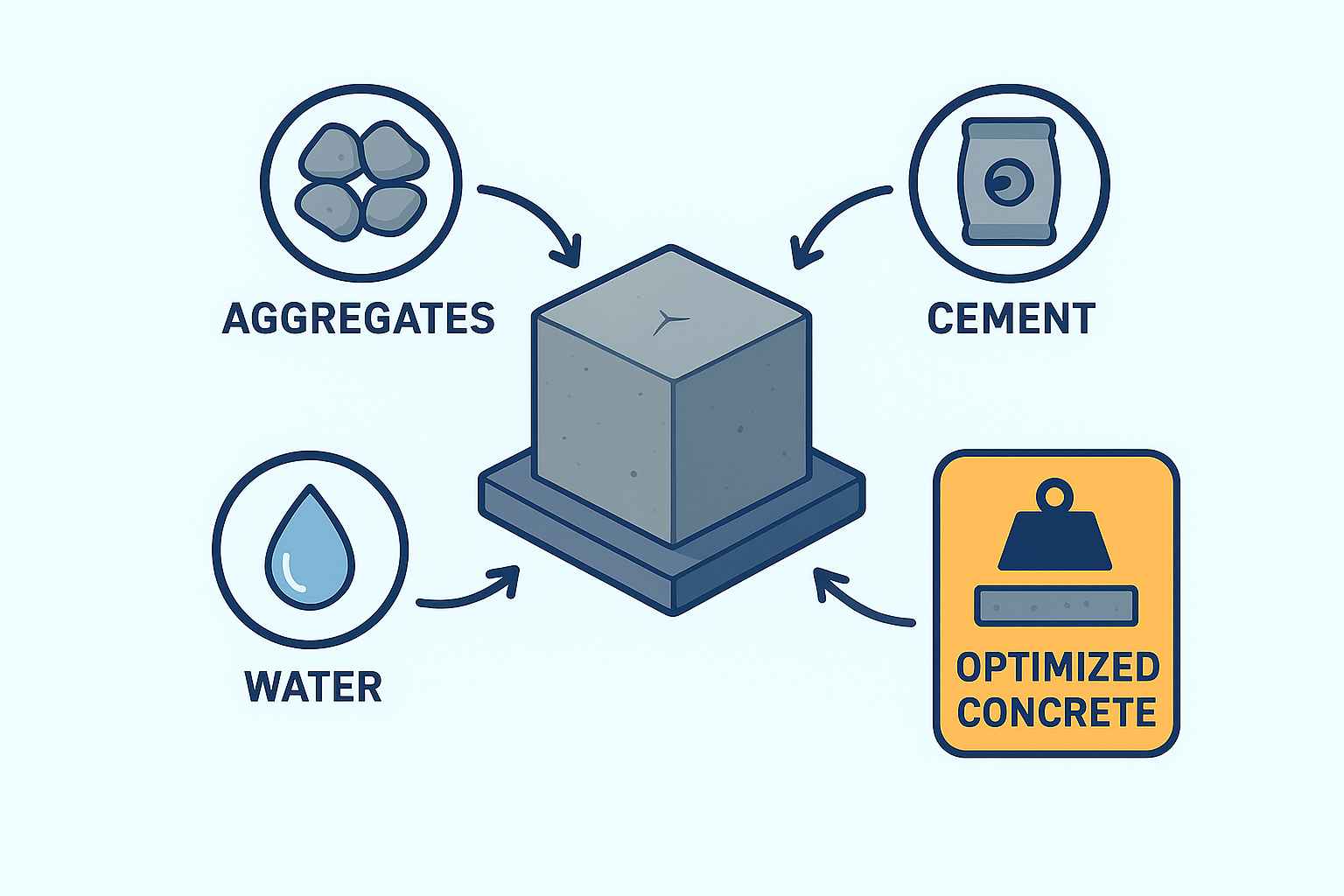

The roof slab leakage could be due to substandard material (concrete) or incompetent supervision — or both. The plumbing issue could be due to untested or uncommissioned water lines before handover. All these points point to the importance of Quality Control (QC) and Quality Assurance (QA) while construction is in progress.

The Difficulties of Substandard Quality

Rectifying such damages in buildings is often more complex than making the original structure in the first place — whether it’s civil, mechanical, electrical, firefighting, or telecom works.

Apart from the hardship, corrective actions cost more money and time, the two most critical components of any project.

Quality is not vague or subjective. Judgment and opinion have no place in measuring or determining quality. Terms like “high quality,” “smooth,” or “satisfactory” often confuse more than clarify.

For example, specifying a wall as “flat” or “reasonably vertical” doesn’t define measurable quality. Instead, a proper specification like “a tolerance of ±3 mm for 6 m in vertical measurements” provides a clear standard.

Impacts of Substandard Quality in Construction

Now it’s easy to realize that quality control and quality assurance must remain top priorities in construction. If not, then why shouldn’t they be?

Several factors may directly or indirectly bear the brunt of poor quality. Some of them are:

1. Time

Any rework arising from non-conformance to approved details, specifications, or contractual requirements results in time-consuming activities.

Depending on the nature and severity of defects, it can delay project schedules by diverting manpower, equipment, and supervision from other works.

2. Cost

A self-explanatory aspect. Any work involving corrective actions or defect rectification means extra cost. It requires additional manpower, materials, and machinery — depending on the type, location, and size of defects.

Sometimes, it even leads to demolition and reconstruction. Clearly, there’s always a price to pay for lapses in quality.

3. Reputation

Quality builds reputation. A product or service that maintains high quality earns user trust. The same logic applies to construction.

Imagine a hotel serving good food with warm hospitality — customers will return and recommend it to others. But if the food quality drops, the reputation suffers instantly. Similarly, builders delivering quality homes earn goodwill and brand recognition, often through simple word-of-mouth.

4. Safety

Many may wonder how quality and safety are interconnected — but they are.

A safety incident can occur due to poor workmanship. For instance, an improperly fixed panel may fall off due to lack of proper anchoring, causing injuries. Though it’s seen as a safety incident, the root cause is a quality issue. In construction, several such examples show how substandard work can become hazardous.

5. Confidence Level of Workforce

Rework or rectification also affects the morale of the workforce. When their effort gets rejected due to poor quality, it lowers motivation and confidence. The pressure to correct mistakes, often under tight deadlines and the scrutiny of supervisors, significantly increases workplace stress.

6. Environmental Impact

Rework generates waste — demolished concrete, discarded plywood, excess materials, etc. Every discarded material represents “embodied energy”—the energy spent extracting raw materials, manufacturing, and transporting it to the site. Rework means this energy was completely wasted, increasing the overall carbon footprint of the project. Hence, maintaining quality is also a sustainable practice.

A Final Sign-Off on Quality in Construction

The impacts listed above are not exhaustive. Poor quality can have far-reaching consequences — even affecting an organization’s financial stability and public image.

To conclude, how can one define Quality?

As per ISO 8402:1994 – Quality Management and Quality Assurance: Vocabulary:

“The totality of features and characteristics of a product or service that bears its ability to satisfy stated or implied needs.”

For the construction industry, quality can be termed as:

“Completion of the project within the scheduled time frame and allocated budget, meeting prescribed standards, guidelines, and obligations as per the contract agreed upon between the parties.”

On a broader perspective, in an industry growing rapidly and competing for relevance, delivering projects with excellence and integrity could well be the true motto of quality.

Quality in construction is not just about meeting standards — it’s about building trust, ensuring safety, and leaving behind a lasting legacy.