Overview on Optimization of Concrete

Optimization of concrete mix design is not yet a common practice in India or even globally. Major codes such as IS, BS, and ASTM do not provide direct guidelines for such optimization. In the absence of codal provisions, researchers and practitioners have turned to international studies and analytical models to explore how concrete can be optimized for both economy and performance.

Some reports/articles in the international journals related to the construction industry covering the importance of optimization are taken as a reference to study the importance of optimization.

A Short History of Optimization of Concrete

The global demand for concrete has driven researchers to explore ways to reduce project costs. Since concrete is fundamental to all civil construction, the focus has naturally turned toward minimizing cement content — the most expensive and energy-intensive component. This approach, known as Optimization of Concrete Mix, aims to achieve the required strength and durability with minimum cement consumption.

What is Optimization of Concrete Mix Design

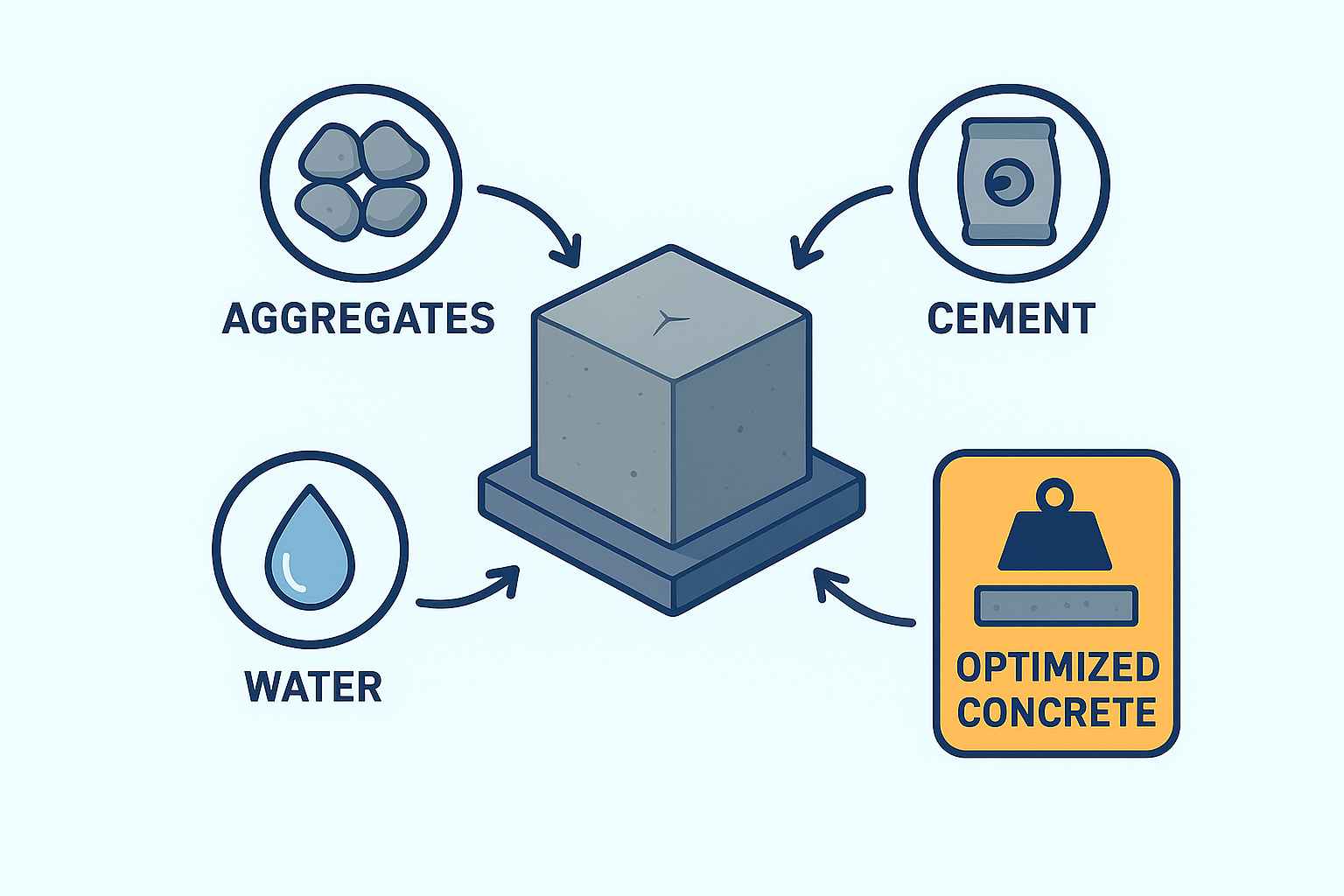

The Process of finding out a cost-effective mix design that satisfies all the required parameters of a concrete mix shall have for its optimum performance.

Optimization of a concrete mix involves determining the most cost-effective proportions of cement, water, aggregates, and admixtures that satisfy all performance requirements — including workability, strength, and durability. The goal is to produce concrete that performs optimally at minimum cost.

Technical Concept

- Factors Affecting Optimization

- Source and properties of materials

- Method of preparation and mixing

- Placing, compaction, and curing conditions

- Concept:

Optimization is achieved by reducing cement paste volume through the elimination of voids among aggregates — ensuring denser packing and better particle distribution. - Method:

Use of the Golterman Packing Model, where coarse and fine aggregates are blended in varying proportions to achieve maximum packing density and minimum voids.

Proposed Method.

- Combine aggregates in different proportions to achieve optimum packing and minimum voids.

- Determine cement paste content by adding 5%, 10%, and 15% to the measured void content.

- Prepare mixes based on these combinations and compare their performance with conventional designs.

Does Optimization affect Concrete properties mainly Strength?

Studies have shown that the compressive strength obtained by the packing density approach is comparable to that of the BIS code method for a given water-cement ratio.

(Ref: Concrete Mix Design By Packing Density Method by N. Raj, S. G Patil, B. Bhattacharjee)

The proposed method for optimization

The aggregates will be combined to get the optimum packing combination, and the respective voids in the combination of all aggregates are calculated. The quantity of cement paste will be decided with an increase of 5, 10, and 15% of that of voi,d and mixes for the different combinations will be calculated, and based on this mix will be based. This will be compared with the conventional Method to satisfy the properties.

Different methods for optimization of mix design

8. Classification of Optimization Methods

You’ve done this part very well — just ensure consistent formatting:

| Type | Description | References |

|---|---|---|

| Fully Experimental | Involves extensive lab trials; applicable only to specific materials. | Domone & Soutsos (1994); Ahmad (2007) |

| Fully Analytical (See 1 below) | Uses mathematical models to minimize trials; computer-based optimization. | Yeh (2007); Kasperkiewicz (1994) |

| Semi-Experimental (See 2 below) | Combines experimental data with analytical tools such as neural networks or genetic algorithms. | Yeh (2009); Jayaram et al. (2009) |

| Statistical Methods | Based on factorial design or design of experiments (DOE) for empirical optimization. | Widely used in practical applications. |

1. I.-C. Yeh, “Optimization of concrete mix proportioning using a flattened simplex—centroid mixture design and neural networks,” Engineering with Computers, vol. 25, no. 2, pp. 179–190, 2009.

2. M. A. Jayaram, M. C. Nataraja, and C. N. Ravikumar, “Elitist genetic algorithm models: optimization of high–performance concrete mixes,” Materials and Manufacturing Processes, vol. 24, no. 2, pp. 225–229, 2009.

Conclusion

Optimization of concrete mix design provides a structured approach to achieve cost savings without compromising quality. Although it is not yet standardized in Indian or international codes, experimental and analytical studies indicate that it can lead to significant reductions in cement content, material cost, and environmental impact. Future codal guidelines and digital tools could make optimization a routine part of concrete mix design.